Founded in 2011 under the Indian Companies Act, 1956, STEELTECH began its commercial installation of incinerators of revolutionary Controlled Oxygen Rotating Technology (CORT) in April 2012. Since then the company has installed over 1800 incinerators branded Nowaste, in leading establishments all across India. It is acknowledged as one of the best solutions for eco-friendly solid waste management.

STEELTECH CORT SOLUTION PVT. LTD., has its corporate office in Calicut and manufacturing facility at Malappuram, in Kerala State, India. The company enjoys a wealth of experience and expertise offered by its founder Dr. Kabeersha who has over 45 years in the incineration segment.

Our team of engineers and technicians are experts in designing incinerators from design, development and production to installation. This is why Nowaste incinerators deliver one of the most well designed, functional and cost effective incinerators that meet the customer’s requirements.

R&D

We have a continuous process of R&D at every stage of manufacturing. Our CAD design section takes care of basic engineering designs. Our team of engineers from Electrical, Mechanical, Instrumentation, and Civil are involved in ensuring the best services and customer satisfaction.

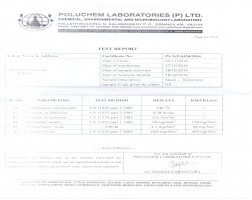

Quality Standards

STEELTECH is an ISO 14001:2004 / ISO 9001: 2008 certified company. We are setting new benchmarks in quality all along the way.

WASTE TO ENERGY

We have changed the perception of waste management from expenditure to earning. There were numerous hospitals and hotels that pay a big amount to remove their wastes and use costly fuel to run their boilers to generate steam or hot water required for their daily activities. Now they utilize “Nowaste” and our Boiler attachment to burn their wastes and to create Steam or Hot water at preferred temperature and pressure by the heat produced in the combustion chamber. Thus they save expenditure of fuel and waste removal.

MARKETING SYSTEM

Our Business associates and Business Development Officers can reach your office upon a phone call. We have a separate cell in our Administrative Office to deal with telephonic/ mail/ website inquiries. Our technical staff will conduct techno-commercial discussion with client subsequent to location visit and assessment of site requirement. They are always glad to demonstrate the function in equipments installed close at hand to the prospective customer.

Get Connect With Us

Facebook

Youtube

Download Brochure